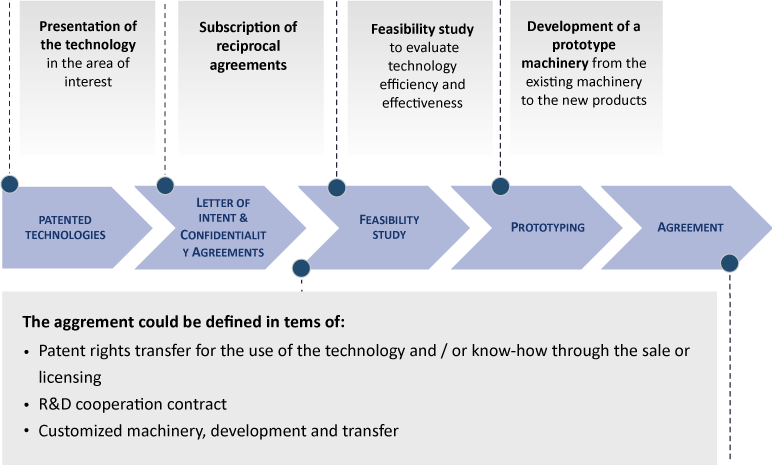

Our business is to provide the most performant, innovative and competitive materials solutions by benefitting from the advantages of our electro-sinter-forging method. Each costumer and market is served with flexibility and with taylor made solutions which will lead through the process from the first acknowledgment of the technology to the definition of the best product for your business.

Technology licensing and know how transfer are critical steps for costumers which aim at a technological acquisition of the ESF technology in their field of use. Exclusivity, transferability, duration, territoriality, exploitability of improvements and guarantee minimum gain are the bases of discussion for these agreements.

Product development is one of EPoS’ greatest expertise. With years of experience in the creation of new products we have learned that knowledge, care, accuracy, precision, focus, open mindedness and experience are the minimal requirements for the development of new materials and products.

Of all the methods to produce materials we have chosen powder metallurgy (PM) for the enormous amount of innovation which is possible is this relatively new branch of metallurgy. PM increase the possibilities to create innovative combination of properties but introduces the complications that arise when dealing with powdery systems: powder size, morphology, physical and chemical nature of the surfaces, flowability, compressibility, constancy of properties, availability on the market and price.

Deep knowledge of materials properties, behavior and cost effectiveness combined with an extensive experimental experience in electro-sinter-forging allow us to help you engineer new materials, new products and new ways to produce them.

Equipment

- ESF machine

- High Energy Ball Mill

- Turbula type mixer

- Metallurgical lab

Initially born as a company with solely productive ambitions, EPoS has not completely lost its devotion to production. For small to medium productions, where margins cannot justify the acquisition of a dedicated machine we can provide productions services.

Our machine for R&D has been designed to handle autonomous automatic production runs of components up to 250-350 mm^2 of projected area and a thickness of 1.5 to 10 mm.

ESF machines for research

We can provide ESF machine for research purposes only. Three different models are available with different size and capabilities.

p-1

Characteristics

- Maximum energy : 40 kJ

- Maximum nominal force: 50 kN

- Maximum peak force: 80 kN

- Structure: C frame

- Axes: double action high speed numerically controlled electrical axes

- Touch screen control panel

p-2

Characteristics

- Maximum energy : 80 kJ

- Maximum nominal force: 90 kN

- Maximum peak force: 120 kN

- Structure: A frame

- Axes: double action high speed numerically controlled electrical axes

- Touch screen control panel

- Projected area of sintered objects (max): 400 mm^2

Options: high precision gravimetric dosing unit, upgrade to 120 kJ of energy

Sintered products

- Projected area (max): 400 mm^2

p-3

Characteristics

- Maximum energy : 120 kJ

- Maximum nominal force: 200 kN

- Maximum peak force: 250 kN

- Structure: A frame

- Axes: double action high speed numerically controlled electrical axes

- Touch screen control panel

- Projected area of sintered objects (max): 800 mm^2

Options: high precision gravimetric dosing unit