2016

Alessandro Fais, Marco Actis Grande and Ilaria Forno

For the first time a dramatic increase in the mechanical properties of a steel powder sintered through a high speed, single pulse, sintering technology is presented in a peer reviewed journal and we have the fortune of being in the prestigious Materials & Design. This paper opens the way for Electro-Sinter-Forged structural steel components with theoretical density and high mechanical resistance.

And we are just at the beginning, just scratching the surface of what can be done with this powerful method. More news to come.

A.Fais

Abstract:

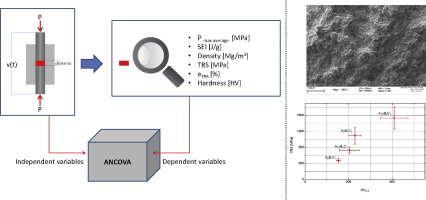

The paper investigates the effects of the processing parameters of an innovative electro-discharge sintering process named Electro-Sinter-Forging applied to a Fe–Cr–Mo powder. Consolidation is obtained by the superposition of a single electromagnetic pulse with a single mechanical pulse. Two high-speed numerically controlled axes are used in the manufacturing process, operating in synchrony with the electromagnetic pulse.

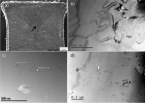

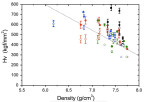

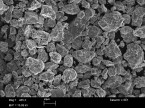

Through an analysis of covariance (ANCOVA) on the experimental data, the differences and correlations in density, pressure before discharge and after discharge, the thermal energy from Joule heat and the transverse rupture strength (TRS) are evidenced. Fracture surfaces are observed and analyzed. A comparison with the conventional press and sinter production process is also performed.