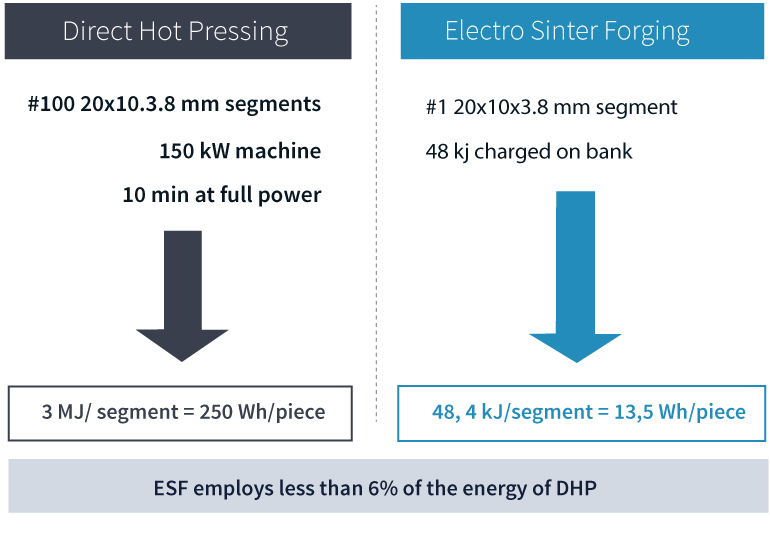

Comparisons with Direct Hot Pressing, DHP have been performed on the side of energetic efficiency Cobalt-diamond metal matrix composites for granite cutting were produced with ESF and the energy employed was calculated and compared to DHP.

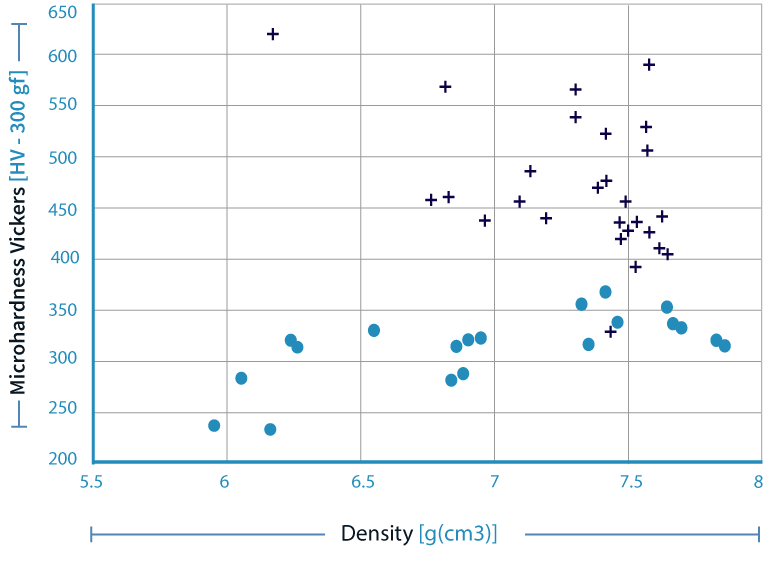

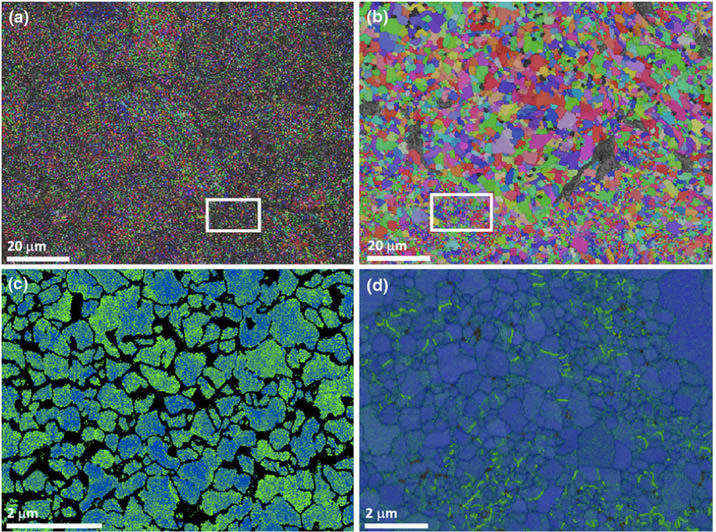

Direct comparison with Spark Plasma Sintering has been made on a nano-crystalline iron alloy to compare the characteristics of the two processes (“Dislocation configurations in nanocrystalline FeMo sintered components” – P.Scardi, M.D’Incau, M.Leoni and A.Fais, Met.Mat.Trans.A DOI: 10.1007/s11661-009-9987-x. Besides the differences in processing time (a hundreds of milliseconds in ESF compared to minutes of SPS) and in automation required (ESF has the simplicity of a press whereas SPS requires robots for the handling of the molds and the extraction of the components) there are substantial diversities in the characteristics of the materials produced: microstructurally finer (see figure 1) and harder (see figure 2) materials are the result of the highly metastable ESF/CDS process whereas bi-modal, softer materials are produced with SPS.

Figure 1: EBSD maps of (a) and (c) CDS and (b) and (d) SPS Fe-1.5 % Mo components. (c) and (d) Local misorientation maps refer to the regions in the inset of the upper pictures.